Types of Couplings – A Brief Overview

A coupling is a mechanical device that connects two shafts together, especially for power transfer from the driver side to the driven side. The misalignment error is also considered during this power transfer between the shafts. Here, the operation incorporated or held differs from the clutch arrangement, in which, according to the operator's will, the power disengages and engages. STS Metal Bellow Couplings join two shafts collinear or parallel to each other with the minimum tolerance or sectional gap between them.

The purpose of incorporating a coupling in the transmission of energy is as follows:

a) Power Transmission from the driving to the driven side.

b) Consume the misalignment errors between the axes of the driving and driven side.

c) Consume the vibrations from the driving side that protects the overall system

d) Not partaking in the heat transfer from the motor on the driver side to the driven side.

The domestic electricity generator is the simple and most common example of a coupling application. By applying the energy conservation law, the fuel's chemical energy is transformed into mechanical energy that rotates the shaft. By the engagement of the coupling, the rotating shaft of the generator connects with the electric alternator. Hence, the coupling is a vital part of the transfer of energy from the rotary motion of the engine to the electric alternator shaft. Lastly, the electric alternator converts the mechanical energy of the shaft to electrical energy.

There are two types of couplings:

1. Rigid Coupling

A rigid coupling binds the two modules, components, or classes by its strong coupling. Coupling firmly holds the grip and is able to transfer the power from the driver to the driven side. However, if any alteration is required in the power transfer, it is better to change the modules, components, or classes.

Other examples of rigid coupling include:

a) Muff coupling

This type of coupling consists of a sleeve and key to connect the input and output shafts.

Advantages:

1) Simple and compact has no projecting parts

2) Cheaper

Disadvantages:

1) Difficult while assembling and requires more axial space

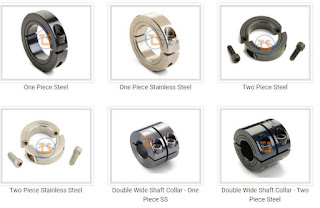

b) Clamp Coupling

Clamp coupling is also known as compression or split muff coupling. The main difference between the clamp and muff coupling is the clamp coupling is divided into two axially symmetric parts that form a coupling.

Advantages:

1) Easy to assemble and disassemble

Flexible Coupling

The fulfilling criteria for the applicability of the flexible coupling are the alignment of the shaft. If not considered, then it can cause cylindrical stresses. It can also return real-time fatigue or wear failures if excessive misalignment is not considered. Examples are Ru-Steel Flexible Couplings, bushed flexible pins, or any other flexible couplings. They are used in transmitting torque from the driven to the driving shaft, considering the misalignment.

Summing up

Hence, these are the couplings and their types. However, if you are willing to buy the best quality couplings, you can refer to "Tradelink Services." Since their inception in 1993, they have been adept in providing top-quality services and products for power transmission. Some of the key products they offer are Keyless Bushe, ETP Keyless Bushes, Samiflex Elastic Couplings, MAV Clamping Units, ROTAR Universal Joints, TRASMIL Cardan Shafts, RULAND Rigid Couplings, and more. For more information, you can visit - https://www.tradelinkservices.in.

Comments

Post a Comment