Why Maintenance & Alignment Is Way Too Important For Coupling

As per our experiences and knowledge, extra care and attention are the keys when it comes to coupling maintenance. Regardless of the type and style of the coupling, you need to consider investing more time in the process since it gets the best possible life and performance out of it. Different types of coupling procedures can require different types of procedures and amounts of time. Some require little to no maintenance at all. On the other hand, some may consume a significant amount of your time.

For example, grid or gear coupling demands strenuous efforts for the coupling. Some additional steps are taken in the process in order to maximize both the life and performance of the coupling. Talking about insert and elastomeric coupling, it's easy to get done with. This is a type of coupling that requires very low maintenance. The best part about it is that the condition can be inspected visually during the operation with the help of a strobe.

From samiflex elastic coupling to ru-steel flexible coupling, the process varies. That being said, let’s shine some light on the importance of maintenance and alignment in the coupling.

- Looking For The Misalignments

Misalignments can cause great trouble. Thus you need to make sure that no such thing exists. The indications of the misalignments usually consist of the uneven wearing of the coupling hubs, binding when we are trying to rotate shafts with our hands, broken or damaged coupling shim-packs or grids.

As per the industrial maintenance technology director, it is crucial that you make use of the proper laser alignment in order to get an accurate alignment.

- Proper Lubrication

Before beginning with the reassembly, it is recommended to use the pre-lube the sliding surfaces of the coupling so that components can have ample freedom of movement. As per the IBT director Mr. Treat, it is recommended to use the re-lubricating after every six months. In case the grease dries, the chances of moisture to get in to become higher, which can end up causing rust and wear whether it’s STS metal bellow coupling or anything like that.

Some Additional Recommendations

In order to ensure robust coupling maintenance, it is recommended not to pressurize the coupling whilst adding the grease by removing both of the lube plugs. It’s because pressurizing can cause leakage. When you pressurize the couplings, the o-rings or seals are compromised, which leads to leakage.

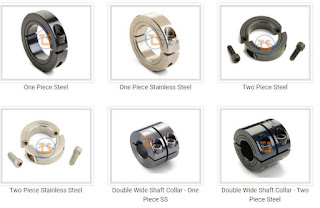

That being said, this was pretty much all you needed to know about the coupling, be it Ruland shaft collars & rigid couplings, or any other type of coupling. However, the maintenance steps vary for some of them.

In case you're looking forward to buying the top-notch couplings at affordable prices, then there's barely any option better than "Trade Link Services". The company offers technologically advanced products that are generally used in several industries. They offer a wide array of industrial products at prices that are sure to leave you amazed. Head to their official website to know more. https://www.tradelinkservices.in/

I like this blog. You have written very great blog. You have given very informative information and one thing also your focused only one thing Samiflex Elastic Couplings. Thanks for sharing!

ReplyDeleteVery nice article with detail on industrial couplings maintance and alignment.

ReplyDelete