Types Of Shaft Couplings You Should Know

Couplings are mechanical elements responsible for 'coupling' two driver elements so that the motion gets transferred from one element to the other. These drive elements are mainly known as shafts and are often seen in automobiles. Shaft couplings add mechanical stability and prevent any problems caused by the misalignment. Couplings are categorized on the basis of their area of application and some of the most common types of shaft couplings are mentioned below:

Flexible Couplings

Flexible couplings are used in areas where the coaxially between connected shafts is not fixed. Also, the occurrence of shocks is very common in these areas where Ru-Steel flexible couplings are used. Flexible couplings are also known as elastic couplings. This is because when these couplings are made, an elastic member is added between two connecting entities.

Rigid Couplings

Rigid couplings are mostly made of aluminum and are used in control applications where two shafts are coaxial to each other. The two most common types of rigid couplings are:

- Muff Couplings - These types of couplings consist of a hollow cylinder that is used to connect two shafts. The tolerance is based on the shaft size. There are two threaded holes to lock the coupling in position.

- Flanged Couplings - As the name suggests, this type of rigid coupling consists of two flanged end pieces. The flanges are connected well with the help of fitted bolts which can be loosened or tightened according to the torque needed.

Bellows Couplings

Bellows couplings are suitable for motion control applications. The reason behind their use is being manufactured with multiple metal convolutions. These couplings offer torsional stiffness and stiffness is very necessary when it comes to positioning applications. You can expect to face fewer issues caused by angular and parallel misalignment if you're using bellows couplings. If you're planning to use these couplings, you can consider ST's metal bellow couplings as a reliable option.

Chain Couplings

Chain couplings are designed for power transmission applications. These couplings are capable of transferring hundreds of horsepower. The applications where chain couplings are used allow angular and parallel misalignment for about 2 degrees and 0.015 inches. You can find special chain sprockets and double large roller chains being installed within chain couplings.

Disc Couplings

Disc couplings consist of one or more disks and are considered power transmission devices. They transfer the torque and tolerate angular misalignment but are able to do so because of the thin metal disks which give them stability. You can find them installed in high horsepower engines and gas turbines.

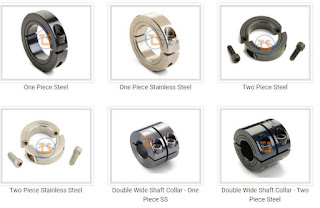

If you need the best shaft couplings for your industrial facility, you can consider the ones offered by "Tradelink Services". Established in 1993, the firm has been providing technologically advanced products for several industrial facilities in India. You can get Ruland Shaft Collars & Rigid Couplings, Samiflex Elastic Couplings, MAV Clamping Units, BAMATEC Spring Couplings, and several other products. Their team of experts has a combined experience of more than 60 years and they take pride in serving several different industries.

Very nice information on types of industrial couplings

ReplyDelete