What is Shaft Collar?

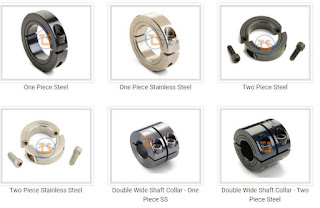

Shaft Collar is one of the simplest components in mechanism design. Shaft Collars can be found in any type of machinery and are accessories to other components. They are capable of fulfilling many roles and hold bearings and sprockets on shafts. It is a component used in motor and gearbox assemblies and serves as a mechanical stop.

There are varieties of factors that determine that a collar is ideal for an application. It is significant to identify carefully all the relevant requirements and limitations of your system before selecting the right Shaft Collar.

- Surface-treatment & Stick-slip: The surface treatment on the soft collar is another factor to control holding power. These collars and screws are made up of stainless steel with black oxide or zinc plated surface finish. It enhances the holding ability and keeps the torque within its design parameters. Screw treatment is actually important for stainless steel Ruland Shaft Collars. Ruland treats all stainless hardware with a formula that provides necessary dissimilar material to prevent galling.

- Installation & Disassembly: Well, it is important to understand how effective the Shaft Collars will be in an application. Some will require adjustment after the initial installation. One-piece set screws are easy to install quickly. Two-piece styles are beneficial as they can be installed and removed without disturbing other elements.

Samiflex Elastic Couplings Guide

The Samiflex Elastic Couplings has been developed and manufactured for industrial application where serviceability is the main issue. It helps in saving in manpower, downtime, is easy to install, economical, and provides trouble-free service. The special feature of the Elastic Couplings is that it is easy to replace the elastic and insert without dismounting the complete drive unit.

Advantages of Using Samiflex Elastic Couplings

- It mounts without special tools.

- Inspection and maintenance are done without dismounting the hubs.

- Different elastic inserts in different applications.

- Ease to mount and alignment.

- It is perfectly suitable for vertical installation.

- It allows friendly service.

- It is a galvanic isolated coupling hub.

STS Metal Bellow Couplings in the Food Industry

Before a delicious piece of chocolate melts into your mouth, many production steps have been executed with absolute accuracy.

- Process Reliability for Stable Quality: The safety Metal Bellow Couplings are at critical points in the production and ensure process continuity. It is important to install the right couplings at key positions to get a reliable result.

- Minimize Damage From Overload: Metal below couplings help in increasing the reliability of many couplings models. Precise installation of the couplings is crucial in order to take full advantage of the technical properties and allow shaft misalignment to be remunerated without transmission failure.

The Final Thoughts!

Trade link services are not only marketing their products but also specialize in the field of mechanical power transmission engineering. They offer internationally and locally assured quality and supplies at competitive rates. They also supply Ru-Steel Flexible Couplings and are recognized as one of the best product service providers in Madras. Get in touch today for more info at https://www.tradelinkservices.in/

Comments

Post a Comment